PEEK is a High performance plastic, which is used in industry versatile, z. B. in the automotive, petroleum or chemical industries. In medicine, PEEK has been proven for several years, including as a material for dentures.

The term PEEK is an abbreviation for PolyEtherEtherKeton. PEEK is a high-temperature polymer characterized in particular by a high temperature resistance, a very good one Mechanic solidity and good Chemical resistance distinguished.

Why is PEEK for the coating of surfaces used?

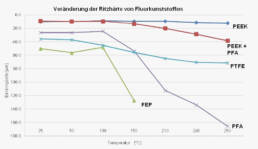

Compared to the conventional materials for coatings, such as fluoropolymers, PEEK can be exposed to higher temperatures without losing its mechanical and physical properties. It's about a very strong polymer; the resistance to abrasion or wear is significantly higher than that of fluoropolymers.

The very good mechanical properties are also due to a excellent creep resistance and fatigue resistance approved. In addition, PEEK has one excellent hydrolysis- and Chemical resistance (but not resistant to sulfuric and concentrated nitric acid). One low flammability as well as the optional possible electrical conductivity complete this 'high-tech' plastic and make it a perfect basis for producing functional coating systems for industrial applications.

Development Non-stick coatings with PEEK

Through intensive research and development work, the Rhenotherm team has succeeded in positive qualities of PEEK polymers with the excellent ones Non-stick properties from fluoropolymers zu the kombinier. The result is innovative Non-stick coatings based on PEEK.

The PEEK coating includes a special layer structure with the high-performance plastic PEEK, which is applied directly to the surface of the workpiece to be coated in combination with fluoropolymers and possibly other additives.

Excerpt PEEK coating systems

Non-stick coating based on PEEK with additive, offers a good non-stick effect, layer thickness 30 - 150 µm, scratch-resistant up to a temperature of 270 ° C

Non-stick coating based on PEEK with fluoropolymer, is characterized by an excellent non-stick effect, layer thickness 30 - 150 µm, scratch-resistant up to a temperature load of 230 ° C

Non-stick coating based on PEEK with fluoropolymer, is characterized by a special hardness and very good non-stick effect, layer thickness 30 - 150 µm, scratch-resistant up to a temperature load of 270 ° C

reliable Dry lubrication based on PEEK with additive, layer thickness 30 – 60 µm, scratch-resistant up to a temperature load of 270 °C.

All coating systems based on PEEK have the Color dark brown to black, are to FDA approved for food and chemically resistant (except against sulfuric and concentrated nitric acid). If necessary, all systems can additionally with a electrical conductivity (in the range <106 Ohm).

Benefits of non-stick coatings with PEEK

Compared to conventional non-stick coatings, Rhenotherm's PEEK coating systems are characterized by:

- improved scratch resistance,

- longer lifetime,

- higher temperature resistance,

- better water vapor tightness,

- improved Corrosion Protection.

Application examples

Non-stick coatings based on PEEK are particularly suitable for the Food, adhesives, rubber and paint industry, They are particularly suitable for components or surface areas which are exposed to a relatively high temperature load and to which food, adhesives or molten plastics should not adhere.

- Sealing strips or sealing plates

- Lötwellenrahmen

- Sliding plates or slide rails

selection the appropriate PEEK coating

To achieve the best possible performance, our coatings are tailored to your specific application. In addition to the systems listed here, further combination systems are possible!

Before your components are coated in-house, our qualified team will advise you in detail and together with you select the suitable coating system for your application. Even a cost-effective pattern coating of your components is possible.