Cutting and welding of plastic foils, styrofoam, etc. with fluoroplastic-coated resistance wire.

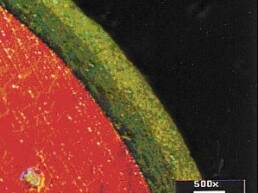

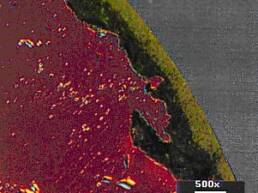

- Additionally optimized pre-treatment and adhesion-enhancing components resulted in improved 3 adhesion.

- Improved non-stick properties due to new hi-tech PTFE system

- Coating: Rhenolease MK II green, Rhenolease MK II gray

- Layer thickness: 15 - 20 µm

- Fluoroplastic: Teflon ™ PTFE

- Max. Operating temperature: 260 ° C

summary table the most common diameters and ohm values

The performance profile of the coating systems patented by Rhenotherm:

These ohms values refer to: THYSSEN CHRONITHERM 80 SI.

Quantity delivered:

- 500m spool / carton

- Packaging unit: 6000m in a carton

- Smaller quantities from 50m and deviating dimensions possible

Your line to us

Please contact us for more information about our wire coating. With our expertise, which is based on over 40 years of experience in the coating business, we always deliver the very highest quality and also help your processes to become more efficient with our wire coating.

Get in touch!