By applying a mixture of PTFE and binder resins or a mixture of polyurethane and binder resins, for example in an O-Ring coating, the surface is provided with an elastic layer having a thickness of about 25 to 35 microns. The connection is firmly bonded to the elastomer and remains elastic. The coefficient of friction is significantly improved. In recent years, there are new demands and trends in an O-ring coating and seals. The automatic assembly, a silicone and an improved paint adhesion, a reduction of friction in dynamic applications, and chemical resistance are increasingly in demand.

Other advantages of an O-ring coating:

- durable low friction coefficient

- long lasting good dry running properties

- no stick-slip effect

- improved resistance to aging

- used in dynamic applications

- may be applied to portions of the rubber seal

O-ring coating (O-Ring)

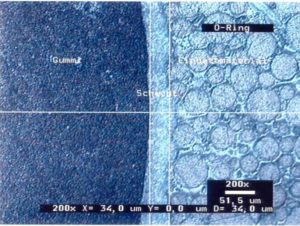

The embedding material, and the substrate are visible in the micrograph