Electrically conductive Coating for elastomers

What does it mean electrostatic discharge ?

Electrostatic discharge is a spark or breakdown caused by a large potential difference in an electrically insulating material, which causes a very short, high electrical current pulse. The cause of the potential difference is usually a charge due to static electricity.

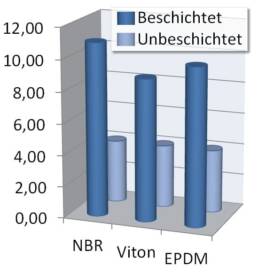

Rhenotherm Mini Parts® has succeeded in using the system Rhenolub MK I RB 30 HD to develop a coating for elastomers that is electrostatically dissipative. This coating can be applied to all elastomers (such as EPDM, NBR, etc.), without affecting the elasticity of the components, as in commercially conductive coatings.

- Friction of different materials on each other

- Transfer of bulk materials and liquids

- Separating two slides

- Running on a plastic carpet

prevention from electrostatic charge

Typical causes electrostatic charge

Electrostatic discharges are prevented by the conductive connection of all metal parts and the incorporation of metallic conductors. These are materials whose electrical conductivity is slightly increased by additives. They safely discharge resulting charges and prevent high-current discharges.

Our electrically dissipative coatings can be used to protect against electrical charging and deflagration.

According to EN 13463-1, it can be assumed that electrostatic charging is avoided if the surface resistance is <= 109 Ohm.

Protect yourself through our conductive coating

Opt for Rhenotherm's electrically conductive coating for elastomers and ensure safety through protection against electrical charging and deflagration. We would be happy to advise you in detail in a personal meeting and show you the many advantages of our conductive coating. Trust in the Rhenotherm expertise!