Rhenoplasma® - The super hard non-stick coating + traction

RP 31 + RHENOLEASE® SF 195

The hardest non-stick coating on the market was specially developed and tailored for challenging applications with the highest demands on wear resistance and hardness.

Conclusion

- nanoscale capping 30-50nm

- covalent (chemical) bond to the substrate

- Pore-deep impregnation of the ceramic layer

- plasma-sprayed ceramic layer, hardness > 1500 HV

- Can also be used on hard anodizing, 300–600 HV

Application

- Parts with the highest mechanical wear stress

- Deflection and guide rollers

- Coils, mandrels

Advantages at a glance

- Pore-deep impregnated, ultra-hard surface

- Covalent (chemical) bonding of the non-stick layer

- Adjustable surface topography

- Excellent non-stick effect against adhesives, adhesive tapes, foils and much more

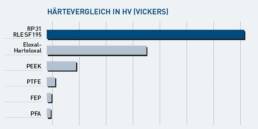

The Hardness

More than 1000 times harder than known coatings, e.g. B. Teflon™

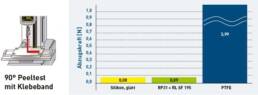

THE NON-STICK EFFECT

40 times better against adhesive tape than PTFE

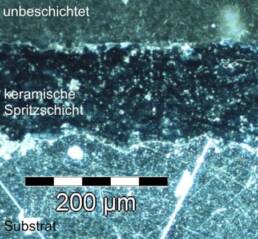

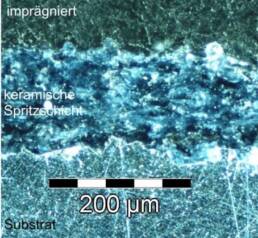

Cross-section:Impregnation of the Al2O3 layer

Coating follows structure

If the tips wear off:

- 90% of the surface remains

- Waterproofing agent protected in the valleys of the hard ceramic microstructure

- Complete preservation of the generated microstructure (no flooding)