Among other things with Teflon ™, PTFE, MFA, PFA, FEP, PEEK, Sol gel for non-stick surfaces, operating temperature up to approx. 260 ° C.

The low adhesion tendency, or rather the Non-stick effect from fluoropolymers such as PTFE, PFA or FEP, depends on their extremely low surface energies. PFA and FEP are copolymers of PTFE. By the theoretical view of the Water contact angle and the resulting balance of forces between adhesion and cohesion result in values for the fully fluorinated plastics, such as PTFE, PFA and FEP, from which one can conclude that the non-stick properties are equally excellent. Pure PTFE, PFA or FEP is rarely used for coating. Coatings are usually characterized in that a so-called primer layer or a primer system, which can consist of several layers, is applied to improve adhesion. In the overall coating system, adhesion promoter additives, pigments, heat stabilizers and a wide variety of binding resins are combined. The selection and mixing ratio of the components as well as their layer structure then determine the functionality and performance of a system. This structure applies to both PTFE-, PFA-, as well as for FEP systems.

Rhenoguard® AS Antibacterial coating

The antibacterial coating in the video. Watch here!

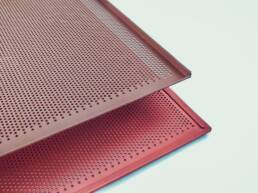

The perfect non-stick coating for your requirements

Our non-stick coatings are suitable for a wide range of applications and some have been designed with specific use cases in mind. From classic non-stick properties to coatings for baking trays and antimicrobial coatings - we will find the perfect product solution to solve your problems and make your business processes more efficient. Please contact us for more information about our non-stick coatings.