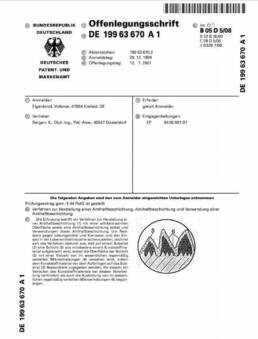

Patent Rhenolease® Lotuflon II, 2011

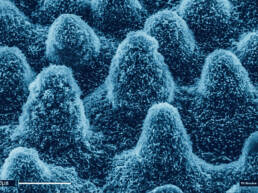

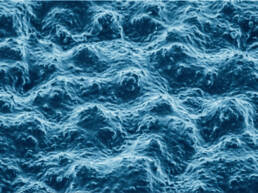

As part of a Research project The development of a superhydrophobic coating with lotus effect was continued and brought to a successful conclusion. Under the name Rhenolease® Lotuflon, three superhydrophobic surface coatings were developed which, in addition to a macro- and microstructure, also had a nanostructure. Water contact angles of 165-175 ° could be achieved. Even honey flows from these surfaces residue-free.

Patent Rhenoguard® Jumbo III, 2002

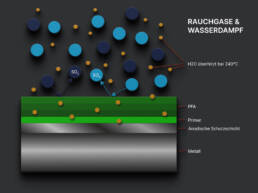

It was found that the previous thick film systems were susceptible in certain applications with particularly high chemical and / or temperature stress. It created tensions in the layer, which led to cracks. Further investigation and improvement has resulted in the Rhenoguard® Jumbo III coating, which is less susceptible to stress, with suitable fillers. In the following section, the principle is clarified:

The upper, pure fluoropolymer layer can not absorb the resulting stresses in the layer and breaks under the load. On the other hand, the plastic layer, which is filled with fillers, can absorb the stresses and remain intact.

Patent Rhenolease® Lotuflon I, 1999

Inspired by the publications and descriptions of the so-called Lotus Effect® by Mr. Barthlott and Mr. Neinhuis in the mid-nineties, Rhenotherm tried to apply this principle to coatings. Through targeted structuring of the substrate and the coating matrix, water contact angles of 130 ° could be achieved. This hydrophobic surface consisted of a macrostructure superimposed by a microstructure. Unlike nature's model, the Rhenolease Lotuflon I system does not yet have a nanostructure.

Patent Rhenoguard® Jumbo I and Jumbo II, 1986

Together with Hoechst, Rhenotherm developed the corrosion protection systems Rhenoguard® Jumbo I + II. The background to this development was that up to this point, there was no coating based on higher-melting fluoropolymers that exceeded the layer thicknesses of 1000μm.

Especially in the chemical industry but thick-film systems were required for high-temperature applications in order to ensure a corresponding lifetime of the coating can.

Up to now layers mostly consisting of a fluoropolymer have been used, which flowed down from the component due to gravity in the sintering process after a certain layer thickness, so that one was usually limited to layers up to 800μm. The solution to this problem was very simple: the combination of a high-fusing fluoropolymer with a low-melting fluoropolymer allowed layers of several millimeters to be applied.

Patent coating of flue gas desulfurization plants (municipal utilities), 1985

Together with Hoechst, Rhenotherm developed the corrosion protection systems Rhenoguard® Jumbo I + II. The background to this development was that up to this point, there was no coating based on higher-melting fluoropolymers that exceeded the layer thicknesses of 1000μm.

Especially in the chemical industry but thick-film systems were required for high-temperature applications in order to ensure a corresponding lifetime of the coating can.

Up to now layers mostly consisting of a fluoropolymer have been used, which flowed down from the component due to gravity in the sintering process after a certain layer thickness, so that one was usually limited to layers up to 800μm. The solution to this problem was very simple: the combination of a high-fusing fluoropolymer with a low-melting fluoropolymer allowed layers of several millimeters to be applied.

Exclusive Rhenotherm coatings for your requirements

Through numerous patents we have secured a unique position in the world of coatings. You too can benefit from exclusive coating methods that you can only find with us. We have been able to convince our customers for decades and would like to be able to count you among them in the future. We would be happy to explain our exclusive coatings to you in a personal conversation.